Core Functions

It is an important protective device for the ship's cooling water system. Main and auxiliary engines and other ship equipment require seawater cooling during operation. The grille guides seawater into the system while intercepting sundries such as aquatic plants, fishing nets, plastics and shells. This prevents foreign objects from damaging the seawater pump, blocking heat exchangers and pipelines, ensures the stable operation of the cooling system, and thus safeguards the safety of the ship's power core. For some ships navigating in ice - covered waters, the grilles are also equipped with anti - icing and deicing devices to prevent the accumulation and freezing of broken ice from affecting water flow.

Materials and Craftsmanship

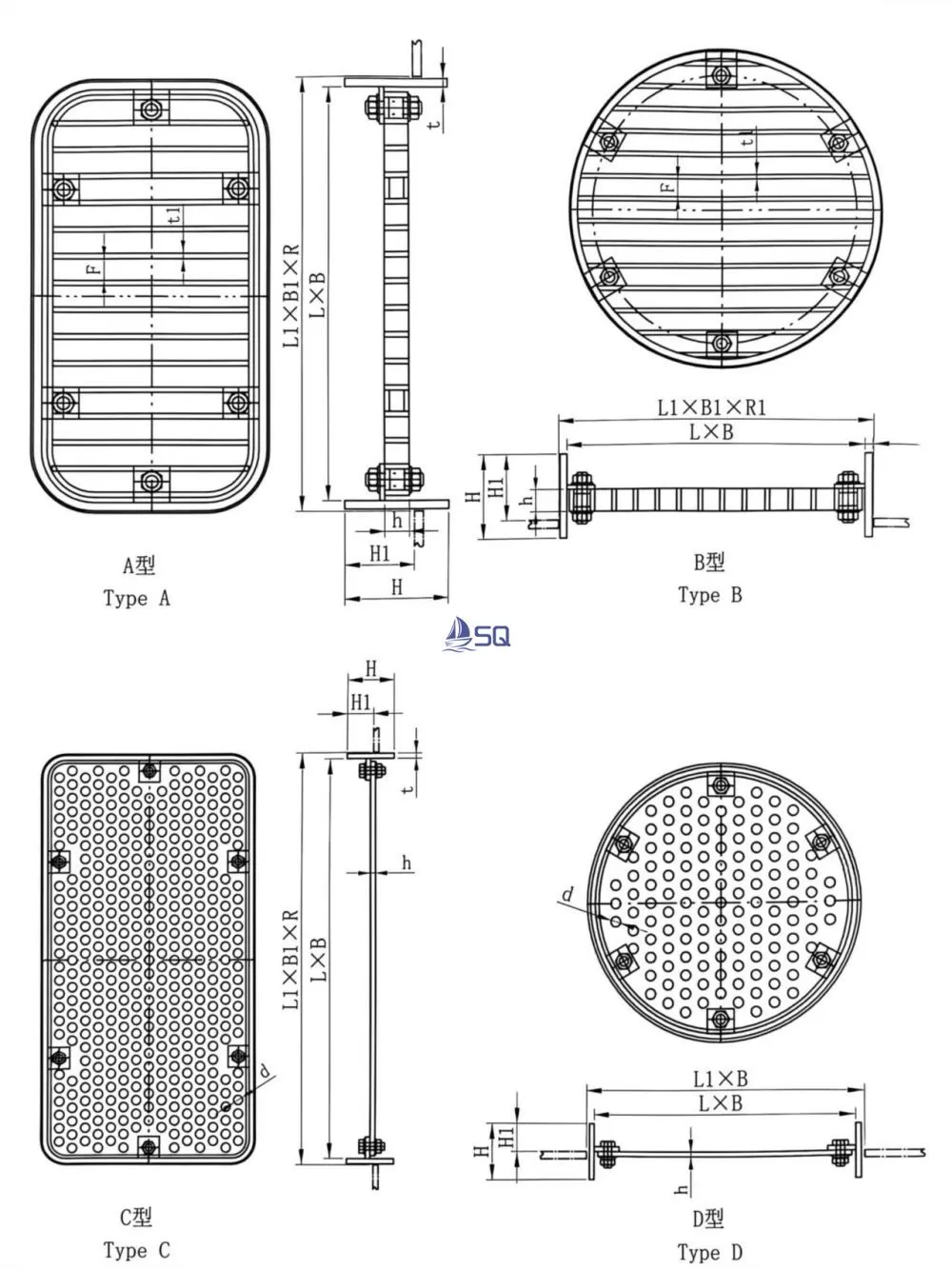

The commonly used material is carbon steel with hot - dip galvanizing. The zinc coating thickness of strip grilles such as Type A and Type B shall not be less than 430g/㎡. Although Type C and Type D drilled grilles also require hot - dip galvanizing, the zinc coating can be slightly thinner. For some special scenarios, corrosion - resistant materials such as stainless steel and cupronickel alloy are also selected. During production, all connection parts adopt full - welding technology to ensure airtightness. After the fixing bolts are tightened, the tail ends need to be sealed with epoxy resin to prevent seawater corrosion.

Installation and Structural Details

The installation is easy to operate. Holes can be drilled at the sea chest according to the outer frame size of the grille, and then the installation can be completed after welding and reinforcement. In terms of structure, Type A grilles adopt different locking methods according to the nominal diameter of the sea valve: the DN100 - DN200 specifications use bolt locking, while the DN250 - DN500 specifications use shaft pin locking. The whole is composed of grille base, grille, studs, nuts and other components. Some can also be cut and installed to adapt to the hull lines.